Did you know? In large-scale construction projects, high power typically demands greater professionalism and operational efficiency. Whether it's new infrastructure like highways, bridges, and large commercial buildings, or the challenging demolition of older structures in renovation projects, these tasks present severe cutting challenges—high-grade steel-reinforced concrete, difficult dismantling of aged structures, and high labor costs. All of these require concrete cutting blades to deliver outstanding performance and lasting stability.

Why Choose ChinShine High-Power Asphalt and Concrete Cutting Blades?

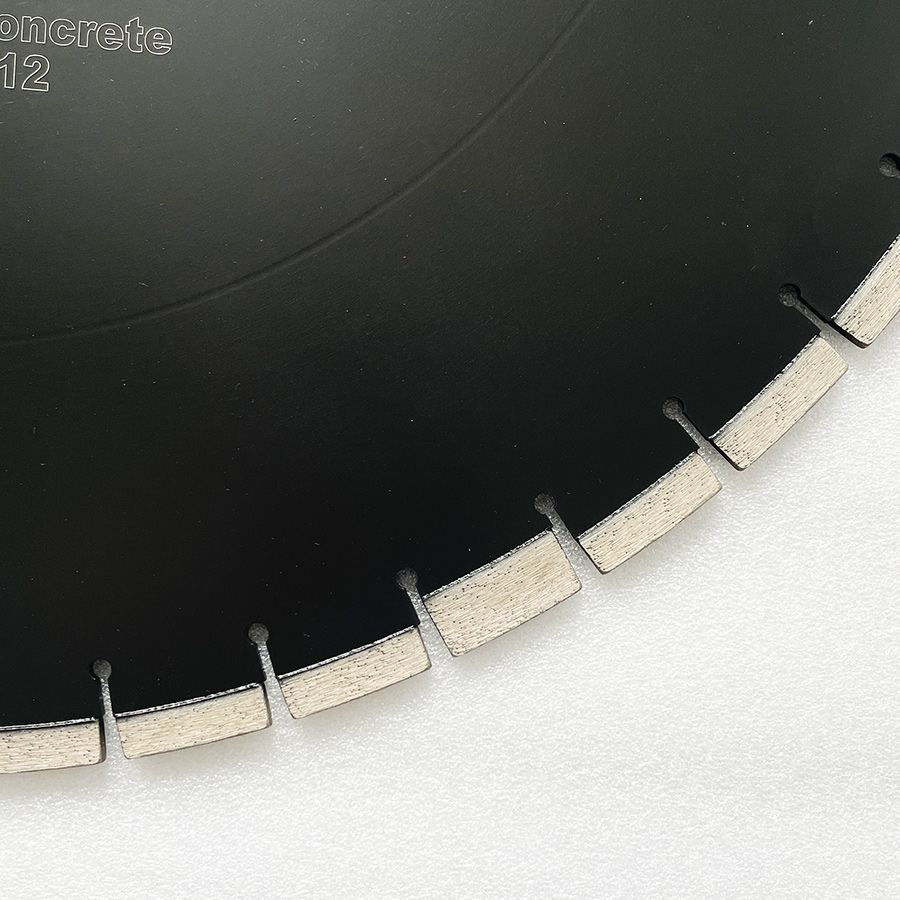

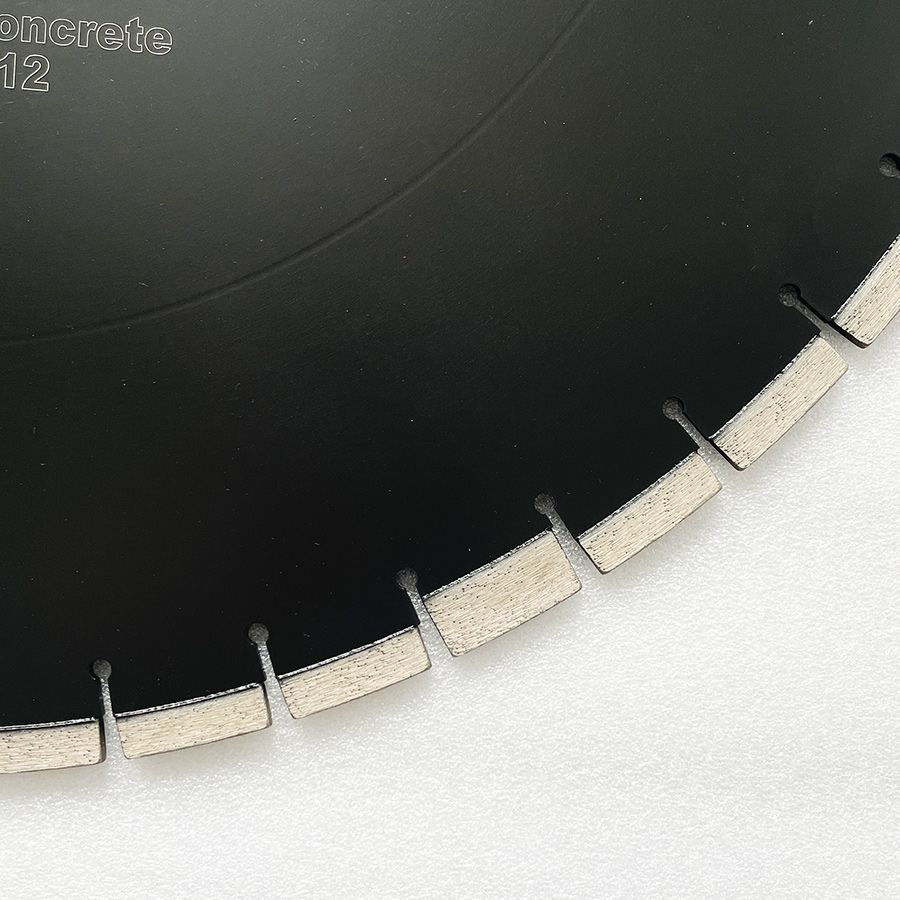

1.Tooth Protection Structure Designed for Harsh Conditions

ChinShine blades are specially engineered with an optimized tooth protection design to combat highly abrasive materials such as quartz sand and granite found in concrete, as well as sticky asphalt in high summer temperatures, effectively reducing clogging and abnormal wear.

2.Rigorous Dynamic Balance and Tension Calibration

High-power blades often operate at higher speeds. Each ChinShine blade undergoes precise dynamic balance and tension calibration tests to ensure smooth, safe, and reliable performance at rated speeds.

3.High-Strength Steel Core and Laser Welding Technology

We use higher-strength, more wear-resistant steel, combined with laser welding technology, for a stronger bond between the segments and the blade. Even when encountering rebar or hard aggregates during cutting, the blade can withstand impact without segment loss or damage.

In summary, ChinShine high-power concrete and asphalt cutting blades are the ideal choice for safely and efficiently tackling the most demanding cutting tasks.