In the production of diamond tools, the use of diamond saw blade is certain dangerous. The diamond segment drop down during cutting may affects the performance of the blade and the operator'safety. Out of the protection and attention to human life, the safety is increasingly valued by manufacturers and users.

Although the current Chinese policies and the diamond tools industry have not made clear and specific regulations on safety of diamond saw blades yet, we can learn from relevant international standards. For example, the new EN13236 standard and the case of notification of recall problems in European countries, in order to improve the production process and improve the quality inspection methods to ensure the safety performance of diamond saw blades.

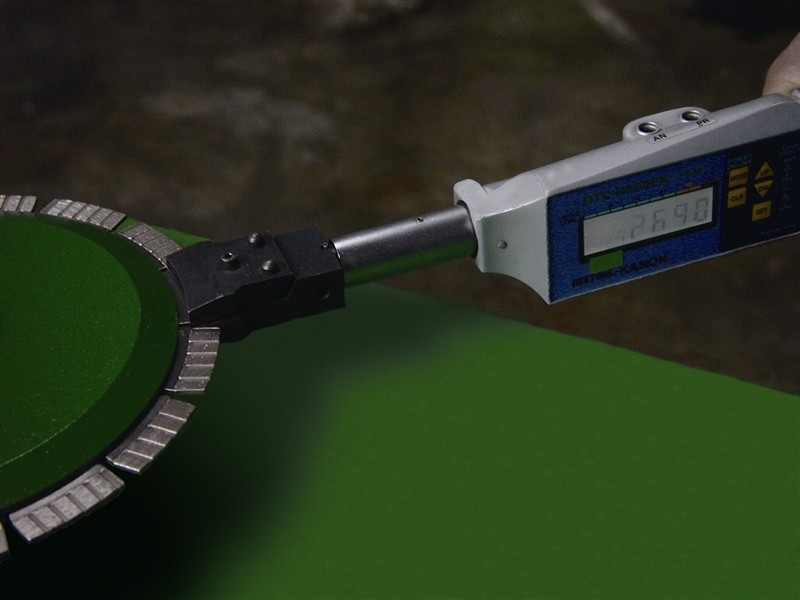

The factors affecting the safety of diamond saw blades

1. For brazing diamond saw blades, the improperly used silver solder(welding solder strip); the welding temperature is not correct; the round teeth of the blade blank are not clean,lead to in weak welding.

2. For sintered diamond saw blades, the sintering process parameters are controlled irrelevantly, the sintering temperature is low, "under-sintering" makes the connect weak between the blade core and diamond segments, and the blade core itself has low strength and is fragile.

How to improve the safety performance of diamond saw blades?

1. For sintered diamond saw blades, optimize the design. Use low oxygen content metal powder; change the outer circle shape of the blade blank to "swallow teeth shape" to improve the bonding strength between the diamond segments and blade core.

2. Optimize the production details. The blade core tooth part adopts the "copper plating" ; adopts the cold pressing and hot sintering; adopts the hot pressing-fusion welding (ie, laser welding).

In traditional high-frequency welding, the bonding strength of the welding seam (especially at high temperature) is not high enough. During cutting, accidents such as the diamond segment dropping and hurting people are prone to occur, the safety and reliability of the diamond saw blade is not good enough. However, laser welding uses a focused laser beam as energy, and uses a penetration welding mechanism to melt the transition layer and substrate of the diamond segment to form a strong welding. Even if the diamond blade or diamond core drill bit is not cooled by water, it can still be used. It ensure high welding strength and the safety.

For more information about the safty of diamond saw blade and its performance, please contact ChinShine Company.

Related Articles:

1.Solutions for diamond saw blade problems -Tips & Troubleshooting

2.How to maintain the diamond saw blade?

3.What is the affection on distance of diamond segments?

4.What is the feedback about ChinShine diamond cutting disk for granite and slate?

5.How people talking about ChinShine diamond cutting disks?

tags :

scan to wechat: