Diamond Blade Become Blunt

The bond of diamond segment is too hard; read the diamond blade instruction and check if you are use the right diamond saw blade. Glazed segments can be opened up by cutting the abrasive material, such as brick and concrete. Make sure the cutting saw has enough horsepower for the diamond blade, you can also check if the drive belts of cutting saw need tp be retensioned.

Blade Blank Loss its Tension

To make a premium quality diamond blade, not only about the quality diamond segments, but also about the blade blank. If blade blank loss tension, maybe the steel blade blank has been overheating. Ensure sufficient water supply for wet diamond cutting blades. If the diamond segment bond is too hard may causing the blade to deviate the cutting. Check machine is running at the correct RPM that there is no wear on machine bearing shaft and that the flanges are in correct and same size. Ensure diamond cutting blade is secure and not spinning on the spindle. Check that the drive pin is in right place. At last, make sure that the diamond saw blade cuts in straight lines only.

At last, if you can't find out the problem, check if the blade blank has been used for many times, you may need to change a new diamond saw blade.

Diamond Blade Overheating During Cutting

Overheating is the common cause of diamond blade failure, overheating causes problems such as loss of tension, blade blank cracks, diamond segment broken and even drop off. People can see the diamond segment or close to the segments become black. For wet diamond saw blades, inadequate water supply can be caused by blocked or damaged feed inlets. Trickle feed for dust suppression van cause excessive abrasion. Do not let diamond blade cutting under heavy pressure, diamond saw blade cut freely is the best way.

Uneven Diamond Segment Wear Off

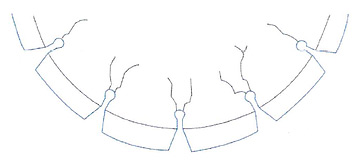

Wet diamond blade cutting without feeding enough water, generally on one side of diamond segment. Check water feeding system, ensure water is equally distributed to both sides of the diamond blade.

Diamond segment is worn out of round due to bad bearings or worn shaft. Replace good quality bearings or shaft as required. Segments worn in one side reducing side clearance (check alignment). Check wheels and wheel alignment on cutting saw.

Diamond Blade Out of Round

Diamond blade shaft bearing may be worn. Change new bearing and ensure regular lubrication. The diamond blade is too hard for the material being cut, resulting in the diamond blade hammering and glazing. Choose right diamond blade with a softer bond. The machine spindle may have a groove scored in it as a result of a previous blade slipping on the spindle.

Steel Blade Blank Cracks

Diamond segment is too hard for the material being cut. Excessive cutting pressure, resulting in the blade blank bending and flexing. Insecure mounting causes fluttering of the blade. Ensure diamond blade is correctly mounted, drive pin used clamp nut is tightened.

Moreover, check if the blade blank has been used for many times. In stone industry, many people use the old blade blank to reweld diamond segments on, best quality blade blank can be welded segments for over 10 times.

Diamond Segment Cracks or Drop Down/Loss

The bond of diamond segment is too hard. Change the diamond saw blade with a softer bond segment. Peripheral speed of diamond blade too high, check rotational speed of the blade.

The cutting materials is not fixed properly, it may causing the diamond blade to twist or jam during cutting. Twisting or turning the machine while the diamond blade is in the cut. Blade flanges are worn or deformed and fail to provide support, causing the blade to deflect in the cut. Foreign material between the flange and the blade blank causing the bade to flutter, resulting in diamond segment loss due to impact or fatigue.

Related Articles:

1.What is the diamond segment welding technique? How to weld diamond segments correctly?

2.Use Dry Or Wet Diamond Blade While Cutting?

3. How do you choose the perfect diamond circular saw blade?

scan to wechat: